Build Your Own King Platform Bed

Building a king platform bed offers a rewarding project for DIY enthusiasts, providing a customized sleep solution tailored to specific needs and aesthetics. This guide outlines the process, encompassing design considerations, material selection, construction steps, and finishing touches, enabling individuals to create a sturdy and stylish centerpiece for their bedroom.

Planning and Design

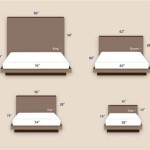

Before embarking on the construction phase, careful planning is essential. Determining the desired dimensions is the first step. Standard king-size mattress dimensions are 76 inches wide by 80 inches long, but variations exist. Adding a few inches to these measurements on all sides allows for bedding overhang and creates a visually pleasing frame. Sketching a design and noting the dimensions helps visualize the final product and ensures accurate material calculations. The height of the platform is another consideration, influenced by personal preferences and storage needs. A higher platform offers ample under-bed storage, while a lower profile provides a more contemporary aesthetic.

Considering the room's existing décor is crucial for cohesive design. The bed's style should complement the overall aesthetic, whether minimalist, rustic, or modern. Choosing materials and finishes that harmonize with the existing furniture and color palette ensures a harmonious bedroom environment. Factors like the room's size and layout should also influence the design, ensuring the finished bed fits comfortably without overwhelming the space.

Material Selection and Preparation

Choosing appropriate materials is paramount for a structurally sound and aesthetically pleasing bed frame. Common choices include solid wood like pine, oak, or maple for a classic look, or plywood for a more budget-friendly option. Metal frames offer industrial aesthetics and exceptional durability. The chosen material dictates the necessary tools and construction techniques. For wooden frames, essential tools include a saw, drill, screws, wood glue, and measuring tape. Metal frames require metal cutting tools, welding equipment, and appropriate fasteners.

Once materials are acquired, preparation is key. Cutting lumber to the specified dimensions according to the design plan is the first step. Ensuring accurate measurements and straight cuts is crucial for proper assembly. Sanding all wooden pieces creates a smooth surface, enhancing both the aesthetics and the finish application. For metal frames, cleaning and preparing the metal surfaces for welding or joining is essential.

Assembly and Construction

Assembling the frame starts with constructing the platform's base. This typically involves creating a rectangular frame using the cut lumber or metal sections. Supporting beams are added within the frame to provide structural integrity and prevent sagging. The spacing of these supports depends on the chosen material and the anticipated weight. Joining the pieces can involve screwing wooden components together, welding metal sections, or utilizing appropriate joinery techniques depending on the chosen material.

Once the base is complete, the next step is to add the side rails and headboard, if desired. These elements provide support and enhance the bed's aesthetic appeal. Securely attaching these to the base is crucial for stability. The headboard can be a simple panel or a more elaborate design depending on personal preference and skill level. Adding legs or casters to the base is optional, depending on the desired height and mobility.

Finishing Touches

After the frame is assembled, finishing touches complete the project. Sanding any rough edges ensures a smooth and polished feel. Applying a finish protects the wood and enhances its appearance. Options include paint, stain, or clear sealant, depending on the desired aesthetic. Allowing ample drying time between coats ensures a durable and even finish. For metal frames, applying a rust-resistant coating protects the metal and enhances its longevity.

Finally, placing the mattress atop the completed frame completes the build. Adding bedding and pillows creates a comfortable and inviting sleep space. Regularly checking the frame's stability and tightening any loose screws ensures the bed remains sturdy and safe over time.

Customization and Enhancements

Building a platform bed provides ample opportunities for customization. Integrating storage drawers beneath the platform maximizes space utilization. Incorporating built-in lighting, such as LED strips along the underside of the frame, adds ambiance and functionality. A custom headboard design, incorporating shelves or upholstery, further personalizes the bed and enhances its aesthetic appeal. These customizations create a unique piece of furniture tailored to individual needs and preferences.

Easy Diy Platform Bed Frame For A King With Instructions

How To Build A King Size Platform Bed Under 100 Twin Civet

Diy King Size Platform Bed Howtospecialist How To Build Step By Plans Frame

Diy King Size Bed Free Plans Shanty 2 Chic

:max_bytes(150000):strip_icc()/buildsomething-d9182ea947314a8dbbba2bc9f0708019.jpg?strip=all)

14 Free Diy Platform Bed Plans

Easy Diy Platform Bed Frame For A King With Instructions

Build Bed Frame King Size Diy

Diy Bed Frame Wood Headboard 1500 Look For 200 A Piece Of Rainbow

Diy Storage Bed Printable Woodworking Plans And Tutorial

Easy Diy Platform Bed Frame For A King With Instructions