Building a Plywood Base for a Queen-Size Bed: A Comprehensive Guide

Creating a sturdy and reliable bed frame is an essential step in building a comfortable and supportive sleeping space. While commercially available bed frames offer convenience, building a plywood base for a queen-size bed provides a cost-effective and customizable option. This guide will provide a comprehensive overview of the materials, tools, and steps involved in constructing a strong and durable plywood bed base.

Choosing the Right Plywood

The foundation of any bed base lies in the plywood selected. Opting for a high-quality plywood ensures longevity and stability. For a queen-size bed, consider using plywood with a thickness of at least 3/4 inch. This thickness provides adequate support for the mattress and prevents sagging over time. Additionally, select plywood with a high-quality core, such as hardwood or birch, for increased strength and durability.

Consider the following factors when selecting your plywood:

- Thickness: 3/4 inch or thicker is recommended for a queen-size bed.

- Core type: Hardwood or birch cores provide superior strength and durability.

- Quality: Choose plywood with a smooth surface and consistent thickness.

- Finish: If desired, select plywood with a pre-finished surface or consider finishing it yourself to match your desired aesthetic.

Cutting and Assembling the Plywood Panels

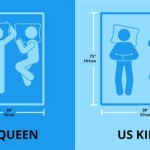

Once the plywood is chosen, it is time to cut and assemble the panels to form the base of the bed frame. The exact dimensions will vary depending on the desired size and style of the bed frame, but a standard queen-size bed base typically consists of two long panels and two short panels.

To cut the plywood, use a circular saw or jigsaw for clean and accurate cuts. Ensure to measure the desired size carefully before cutting, as precise cuts are essential for a stable and well-fitting base. After cutting the panels, use wood glue and screws to connect them at the corners, creating a rectangle.

Here are some additional tips for cutting and assembling the plywood panels:

- Use a straight edge and measuring tape for accurate cuts.

- Use a saw that is designed for cutting plywood to prevent splintering.

- Apply glue and screws to all joints for added strength and stability.

- Pre-drill holes before driving screws to prevent splitting the plywood.

- Use countersunk screws to create a flush surface.

Adding Support and Finishing Touches

After assembling the plywood base, it is crucial to add support structures to prevent sagging and enhance stability. This can be achieved by incorporating slats, crossbeams, or a center support beam. Slats are commonly used to provide airflow to the mattress and create a more comfortable sleeping surface. Crossbeams can be placed across the width of the base, adding additional support and rigidity.

The final step involves finishing the base to complement the desired aesthetic. This can involve sanding the surface for a smoother finish, Staining or painting the plywood to match the existing décor, or adding decorative elements like bed posts or headboards.

Consider these suggestions for adding support and finishing touches:

- Use hardwood slats or wooden dowels for extra support.

- Install a center support beam for heavier mattresses.

- Apply finish coats or sealing agents to protect the plywood from moisture and wear.

- Add decorative elements like molding or trim to enhance the aesthetic appeal.

How To Choose Plywood For Bed Frames

How To Build A Modern Platform Bed For 125 Diy Beautify Creating Beauty At Home

Diy Plywood Bed Modern Builds

Diy Plywood Bed Modern Builds

What Is The Best Quality Of Wood To Make A Plywood Bed Frame Quora

Diy Bed Frame Wood Headboard 1500 Look For 200 A Piece Of Rainbow

Queen Size Modern Farmhouse Bedframe Kreg Tool

Bed Slats Vs Plywood Which Is Best For Your Frame

King Queen Size Adjustable Legs Plywood Bed Frame Base Foundation Box Spring China Hotel Made In Com

How To Build A Modern Platform Bed For 125 Diy Beautify Creating Beauty At Home